Engraving 101: Understanding the four main types of laser

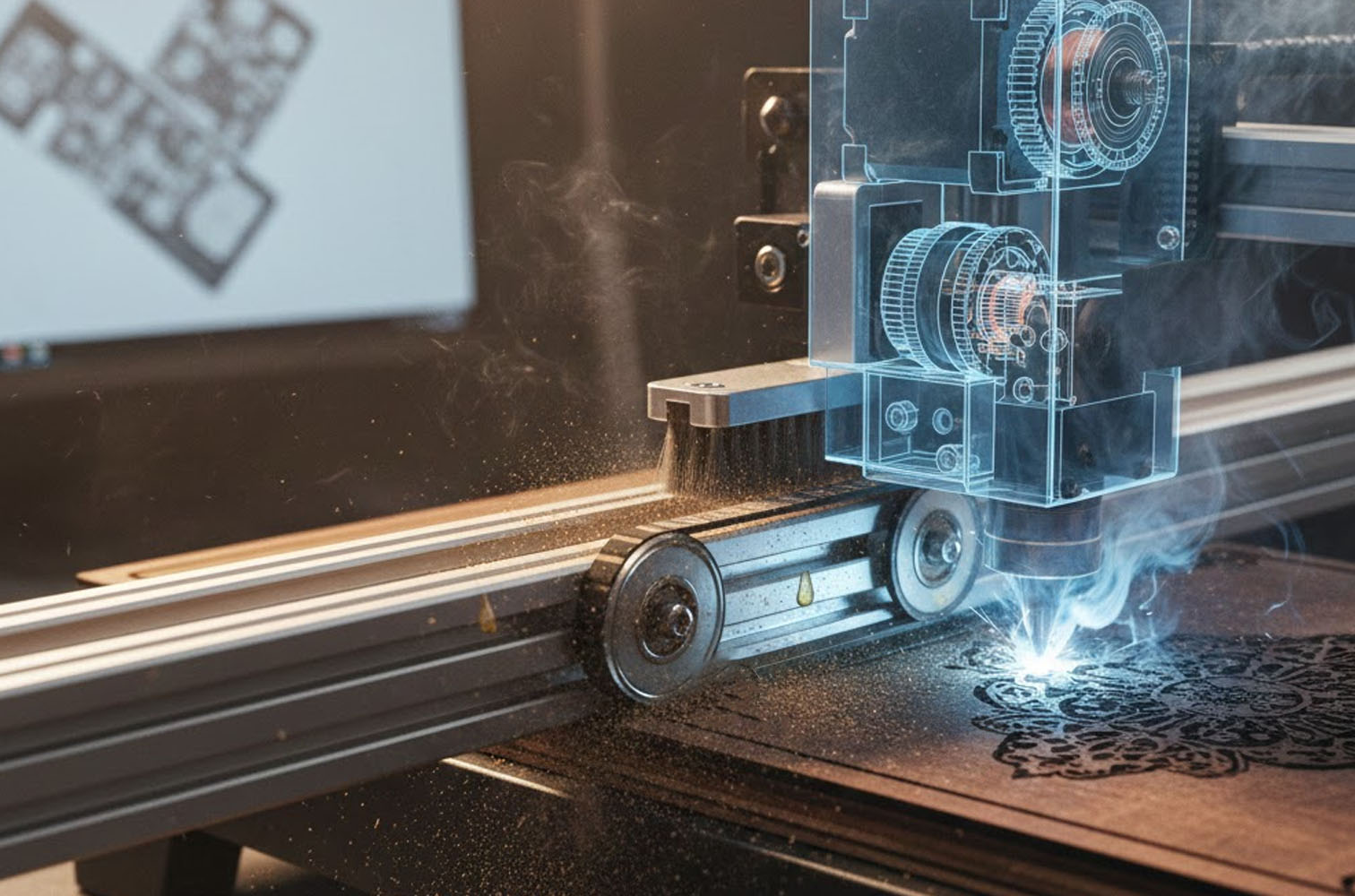

Laser engraving has revolutionised fabrication, personalisation, and artistic expression. But with a plethora of laser types available, choosing the right machine can be daunting.

This guide breaks down the four main laser engraver types: diode, CO2, fiber, and IR, outlining their capabilities, pros, and cons.

Diode Lasers: Entry-level versatility

Diode lasers are the most accessible and affordable option, making them ideal for hobbyists and small businesses. They utilize a semiconductor diode to generate a focused beam of light, typically in the visible blue or violet spectrum. Diode lasers excel at engraving and cutting thin materials like wood, acrylic, leather, paper, and some fabrics. They can also mark coated metals.

- Pros: Affordable and compact; Easy to use and maintain; Relatively low power consumption.

- Cons: Limited power output, resulting in slower cutting speeds and material restrictions; Struggle with reflective or transparent materials; Shorter lifespan compared to other laser types; Generally less precise than other laser types.

CO2 Lasers: Power and Versatility for Non-Metals

CO2 lasers employ a gas mixture, primarily carbon dioxide, to generate an infrared laser beam. They are known for their power and versatility when working with non-metallic materials. CO2 lasers can cut and engrave a wide range of materials, including wood, acrylic, glass, leather, fabric, paper, and rubber. They are often used for intricate designs and thicker materials.

- Pros: High power output, enabling faster cutting and engraving speeds; Excellent for detailed engraving and cutting of non-metals; Widely available and relatively affordable for their capabilities.

- Cons: Cannot directly engrave metals (unless using a marking compound); Larger and more complex than diode lasers; Require regular maintenance, including gas tube replacement; They require a water cooling system.

Fiber Lasers: Precision and Durability for Metals

Fiber lasers utilise fiber optic cables to generate a high-intensity laser beam, typically in the infrared spectrum. They are primarily used for engraving and marking metals. Capabilities: Fiber lasers excel at marking and engraving a wide variety of metals, including stainless steel, aluminum, brass, and titanium. They can also engrave some plastics.

- Pros: High precision and detail; Durable and reliable with a long lifespan; Low maintenance requirements; Excellent for marking reflective metals.

- Cons: Significantly more expensive than diode or CO2 lasers; Primarily limited to metal engraving and marking; Not ideal for cutting thicker metals (requiring very high powered fiber lasers).

IR Lasers: Versatility and precision.

IR lasers or infrared lasers are becoming more and more common. This type of laser can fill a space between CO2 and fiber lasers. IR Lasers can work with plastics, and a wider variety of metals than a CO2 laser. They can also work on some materials that fiber lasers will struggle with. They are gaining popularity in the electronics field.

Pros: Smaller footprint than a CO2 laser; Capable of marking many types of materials; Excellent for very small detailed work.

Cons: Still a fairly new technology to the commercial market; Price point can be high; Material compability still requires testing in many situations.

Choosing the Right Laser:

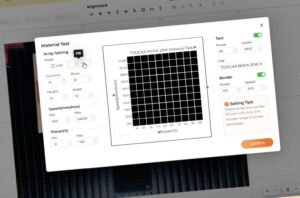

The best laser engraver for you depends on your specific needs and budget. Consider the following factors:

- Material: What materials will you be working with?

- Application: Will you be engraving, cutting, or marking?

- Budget: How much are you willing to spend?

- Space: How much space do you have available?

- Precision: How much detail do you require?

By understanding the capabilities and limitations of each laser type, you can make an informed decision and invest in the perfect machine for your creative endeavors.

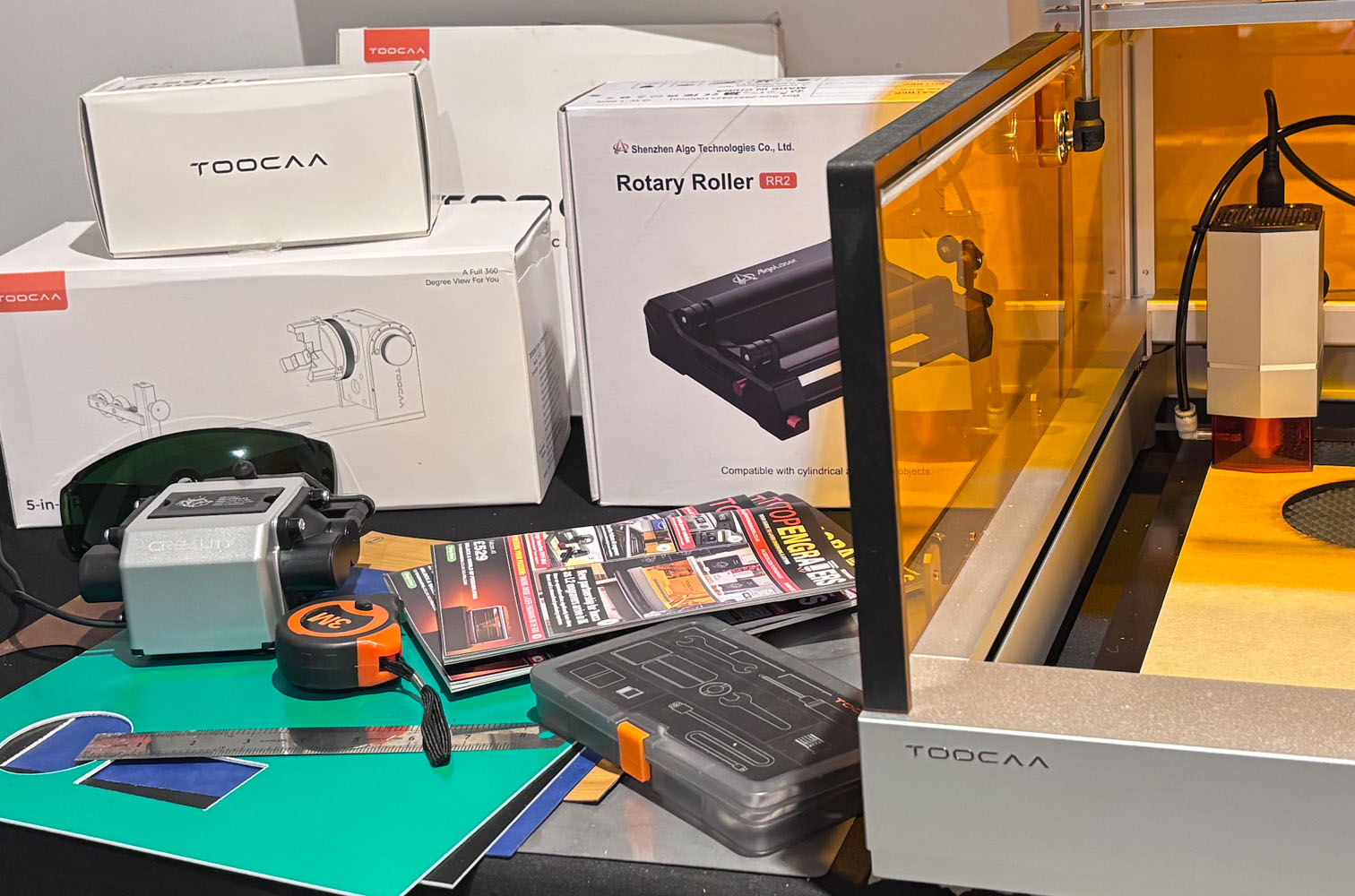

Editor at TopEngravers. Specialising in reviews of new laser engraving products, practical engraving tips, and detailed engraver guides.