Maximise performance: The importance of a clean diode laser

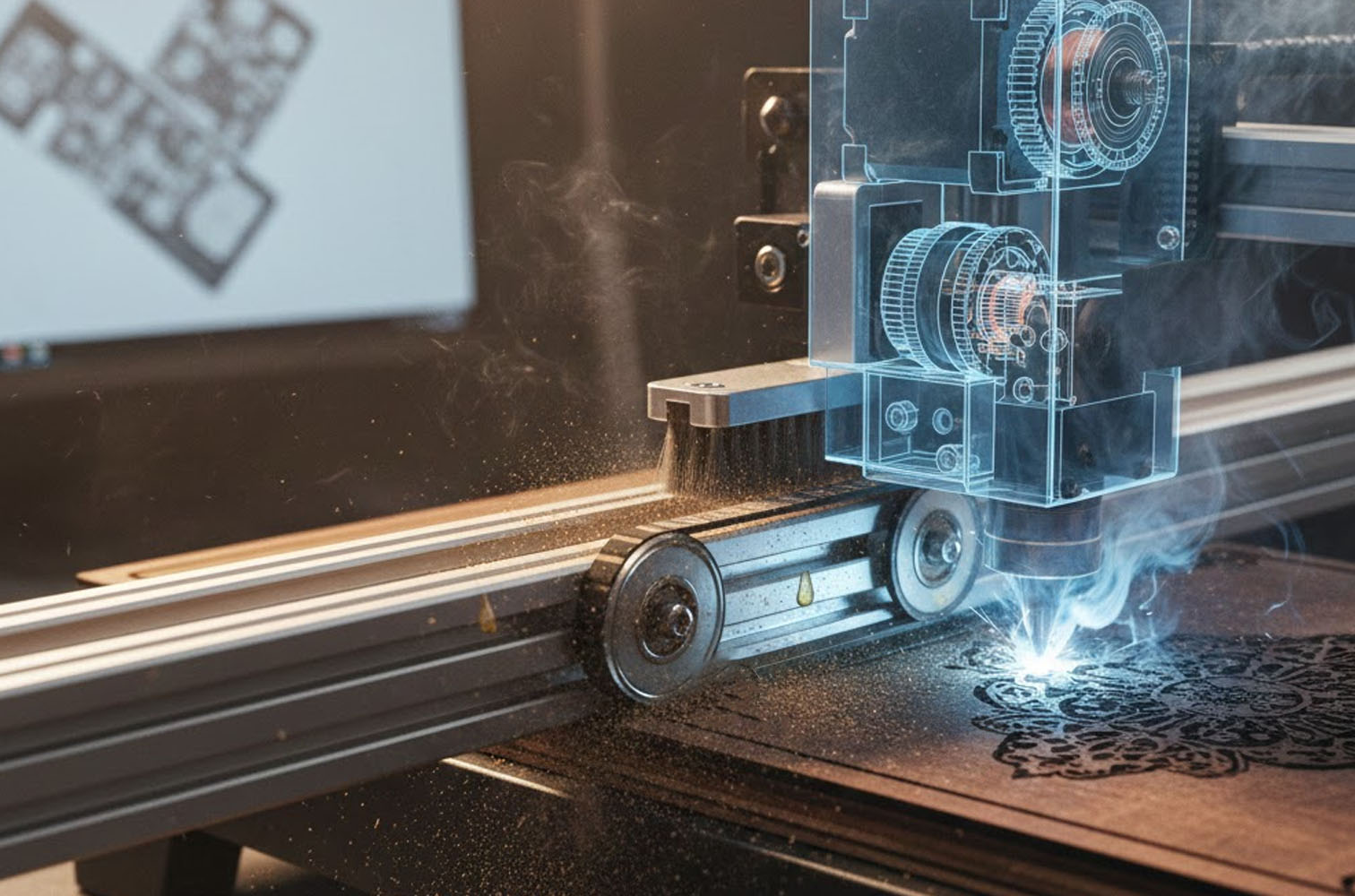

Maintaining a clean laser engraver, especially its diode laser, is paramount for optimal performance, safety, and longevity.

The precision of laser engraving relies heavily on the laser beam’s integrity, which can be compromised by accumulated debris. Here’s a breakdown of why cleaning is essential and some top cleaning tips:

Why Cleaning Matters:

- Maintaining Performance and Efficiency: Dust, smoke residue, and other debris can build up on the laser lens, obstructing the beam and reducing its power. This results in weaker cuts, inconsistent engraving, and a decline in overall efficiency. A clean lens ensures the laser beam focuses correctly, delivering precise and consistent results.

- Preventing Costly Repairs: Accumulated debris can cause the laser to overheat, potentially damaging the lens and other vital components. Regular cleaning helps prevent these issues, saving you from expensive repairs or replacements.

- Ensuring Safety: Laser engravers generate heat and can produce flammable byproducts. Debris buildup increases the risk of fire. A clean machine reduces this risk, creating a safer working environment.

- Consistent Quality: For businesses that depend on laser engraving, consistent quality is crucial. Cleaning the laser ensures that every project meets the required standards, maintaining customer satisfaction.

Top Cleaning Tips:

- Power Down and Unplug: Always turn off and unplug your laser engraver before cleaning to prevent accidental activation.

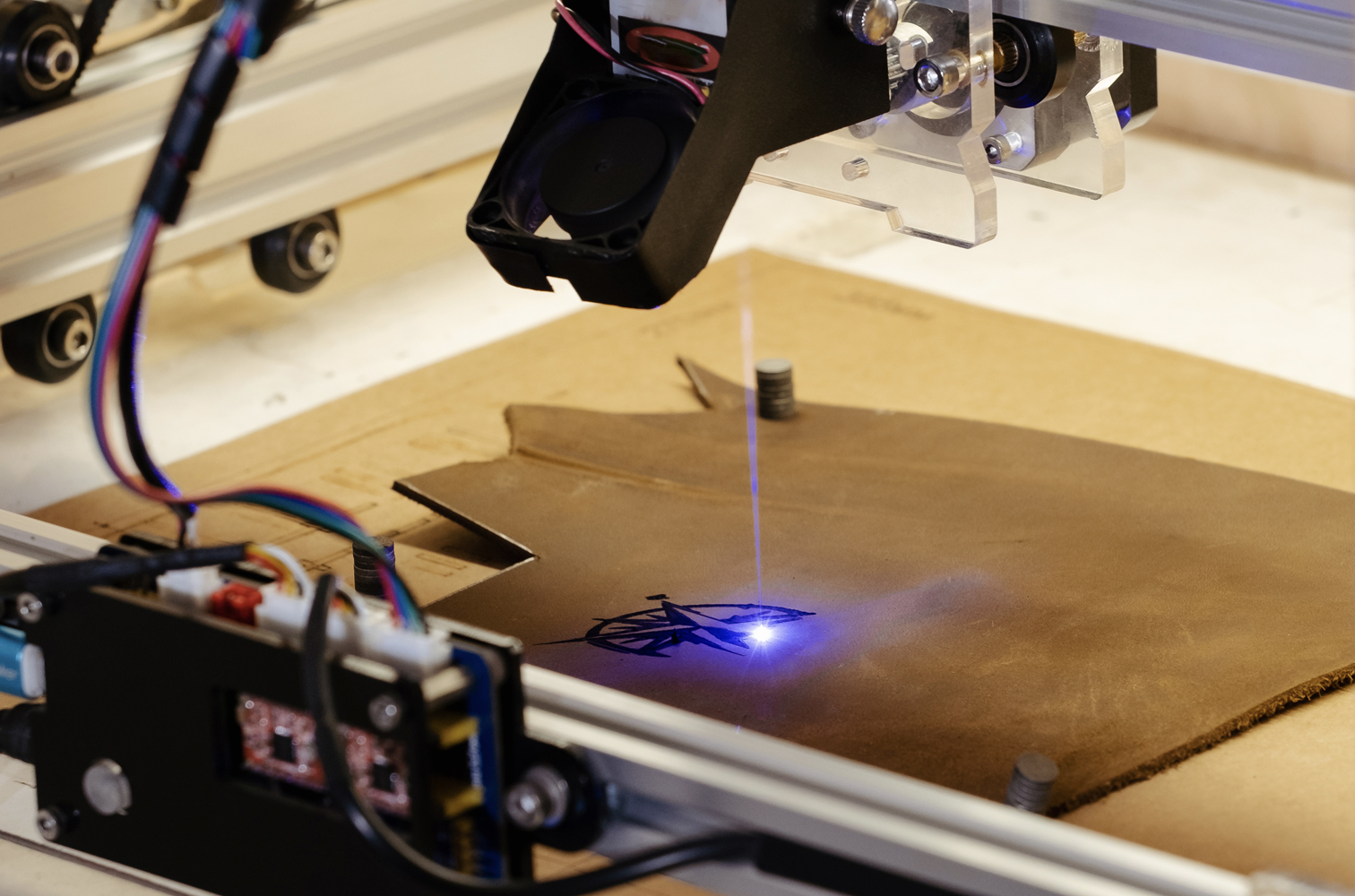

- Clean the Lens: Use a soft, lint-free cloth or lens cleaning wipes specifically designed for optics. Gently wipe the lens in a circular motion, avoiding excessive pressure. For stubborn residue, use isopropyl alcohol or a specialised lens cleaning solution.

- Remove Debris: Use compressed air or a soft brush to remove loose dust and debris from the laser module and surrounding areas. A vacuum cleaner with a soft brush attachment can also be used to remove debris from the work area.

- Clean the Rails and Tracks: Wipe down the rails and tracks with a clean cloth to remove dust and debris. Lubricate the rails as needed, following the manufacturer’s instructions.

- Clean the Exhaust System: Regularly clean the exhaust duct to ensure proper ventilation. Accumulated smoke residue can reduce airflow and increase the risk of fire.

- Regular Maintenance: Establish a cleaning schedule based on your usage frequency. More frequent cleaning is necessary when working with materials that produce a lot of smoke or debris.

- Consult the Manual: Always refer to the manufacture manuals for your specific laser engraver, as there may be specific cleaning instructions for your model.

By prioritising regular cleaning, you can keep your diode laser engraver in top condition, ensuring consistent performance, safety, and a longer lifespan.

Sandy Clarke

Editor at TopEngravers. Specialising in reviews of new laser engraving products, practical engraving tips, and detailed engraver guides.