Leather crafting with light: Mastering diode laser engraving and cutting

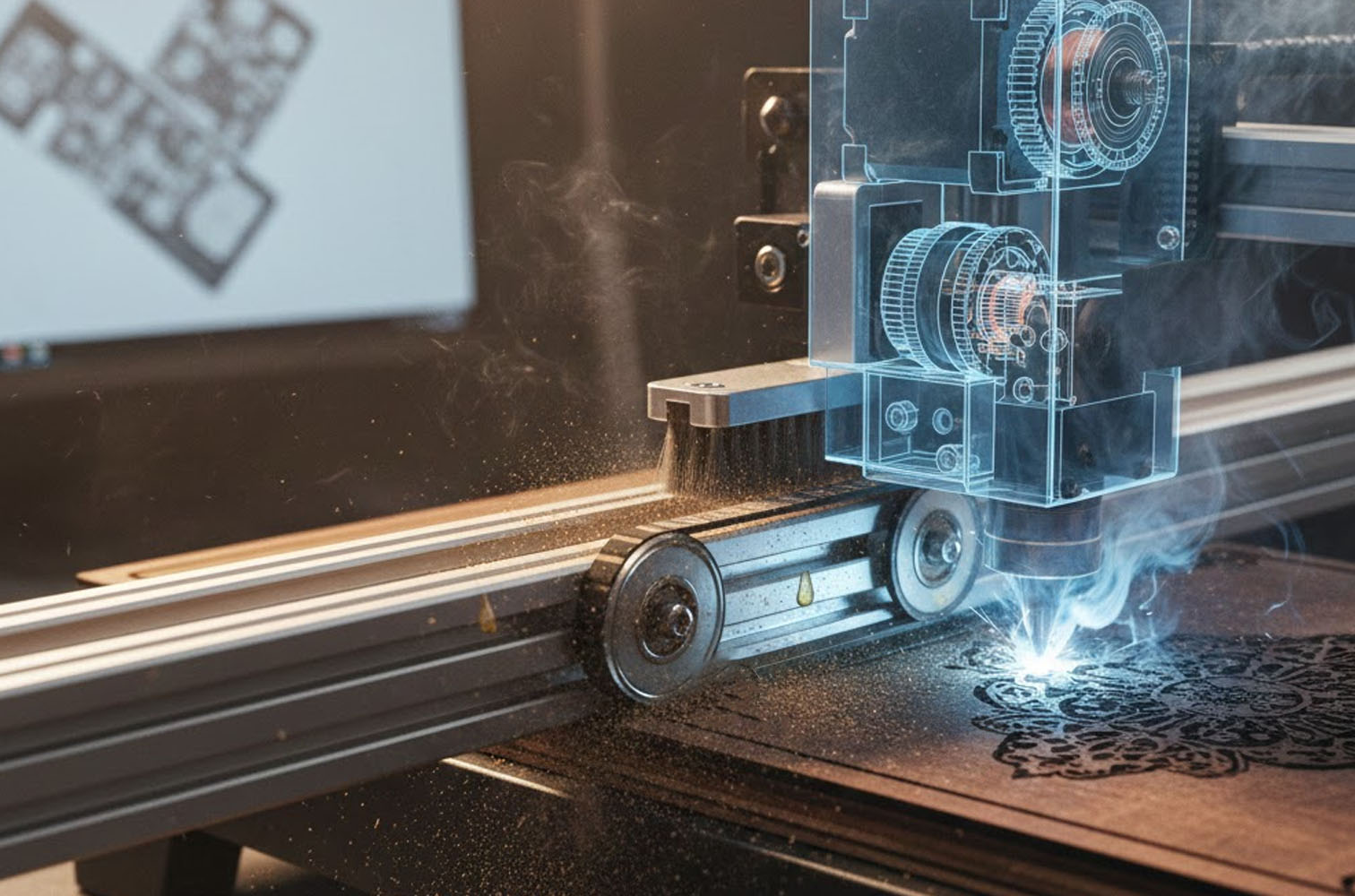

Leather, with its rich texture and timeless appeal, has long been a favourite material for crafting personalised goods. Diode laser engravers have opened up new avenues for leather artisans, allowing for intricate designs and precise cuts that were previously unattainable.

This article delves into the nuances of laser engraving and cutting leather, providing insights for achieving optimal results.

Engraving Leather with Precision:

Diode lasers, particularly those in the 3.5W range, are well-suited for leather engraving. The key to success lies in understanding the interplay between power and speed settings. Lower power settings, combined with slower speeds, produce delicate, shallow engravings. Conversely, increasing power and speed creates deeper, more pronounced marks.

Speed settings play a crucial role in the final aesthetic. Slower speeds allow the laser to dwell on the material for a longer duration, resulting in darker, more intense engravings. Faster speeds create lighter, more subtle effects. Experimentation is key to finding the perfect balance for your desired outcome.

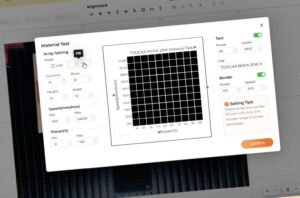

It’s paramount to emphasise the importance of running test engravings on scrap leather before committing to a final piece. Leather varies significantly in thickness, texture, and tanning process, all of which influence how it reacts to laser engraving. A small test grid with varying power and speed settings will provide valuable insights into the optimal parameters for your specific material.

Cutting Leather with Diode Lasers:

Cutting leather with a diode laser requires more power and slower speeds than engraving. While 3.5W lasers can manage thinner leathers, higher-powered diode lasers like 10w, and above provide much better cutting results. It’s often necessary to perform multiple passes to achieve a clean cut, particularly with thicker hides.

Again, testing is essential. Leather can shrink or warp under intense heat, and the smoke generated during cutting can create undesirable discoloration. Finding the optimal settings to minimize these effects requires experimentation.

Safety Considerations:

Working with leather and a laser creates certain safety implications.

- Ventilation: Leather combustion releases fumes that can be harmful if inhaled. Adequate ventilation is essential. Use an exhaust system to direct smoke away from your workspace.

- Fire Safety: Leather can ignite easily. Always keep a fire extinguisher nearby and never leave the laser unattended during operation.

- Eye Protection: Laser radiation can cause serious eye damage. Wear appropriate laser safety glasses designed for the specific wavelength of your laser.

- Material awareness: Some leather dyes or tanning processes can release very dangerous fumes. It is wise to find out as much information as possible about any leather you intend to engrave or cut.

Additional Tips:

- Masking: Applying masking tape to the leather surface before engraving or cutting can help prevent smoke stains and create cleaner edges.

- Air Assist: Using air assist can help to remove smoke and debris from the cutting area, resulting in cleaner cuts and reducing the risk of fire.

- Cleaning: Gently clean the leather after engraving or cutting to remove any residue or soot.

Diode laser engraving and cutting offer a powerful toolset for leather crafters. By understanding the intricacies of power and speed settings, and by prioritizing safety, you can unlock a world of creative possibilities.

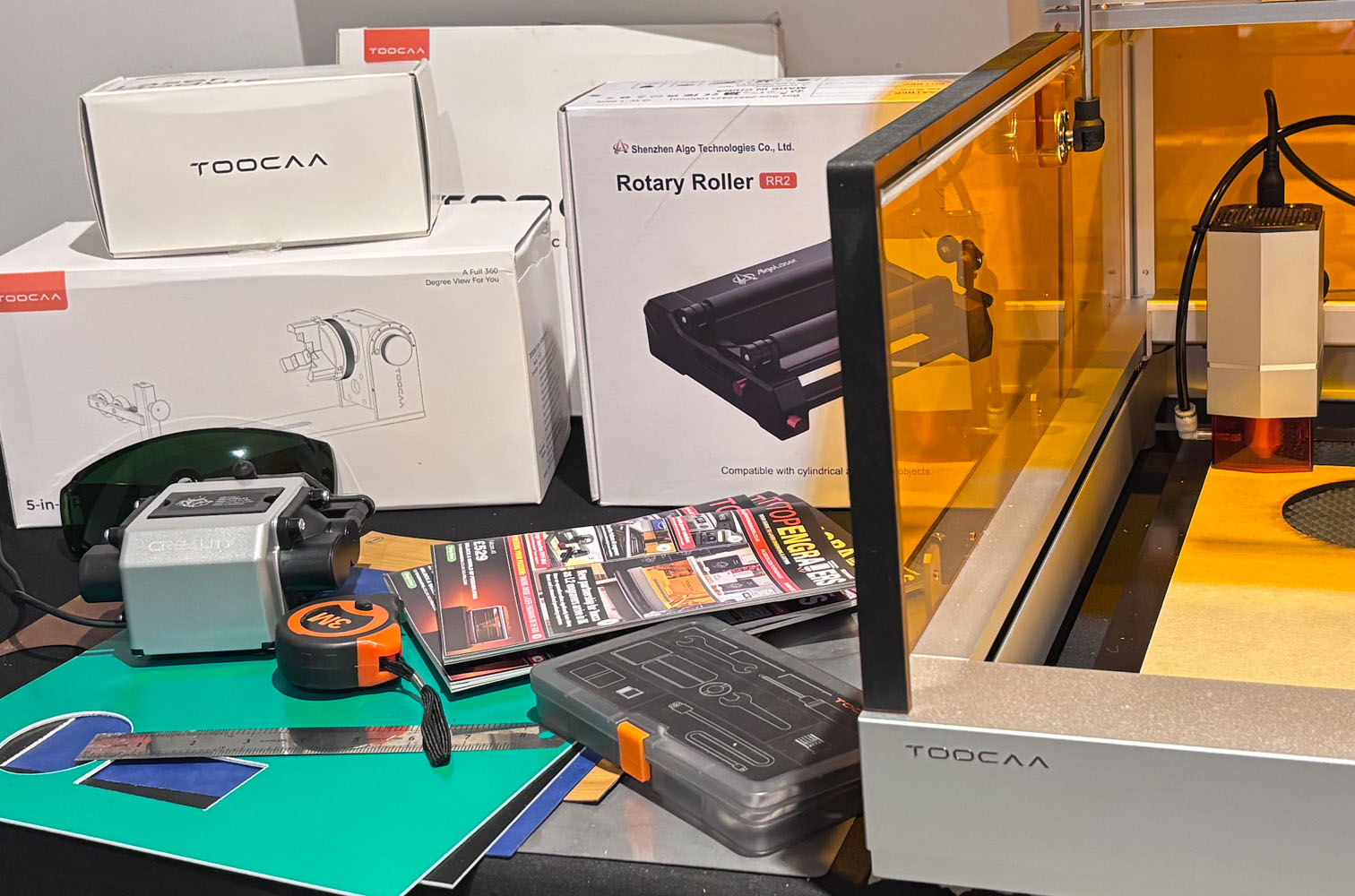

Editor at TopEngravers. Specialising in reviews of new laser engraving products, practical engraving tips, and detailed engraver guides.