Beware the burn: Materials and products to avoid with diode lasers

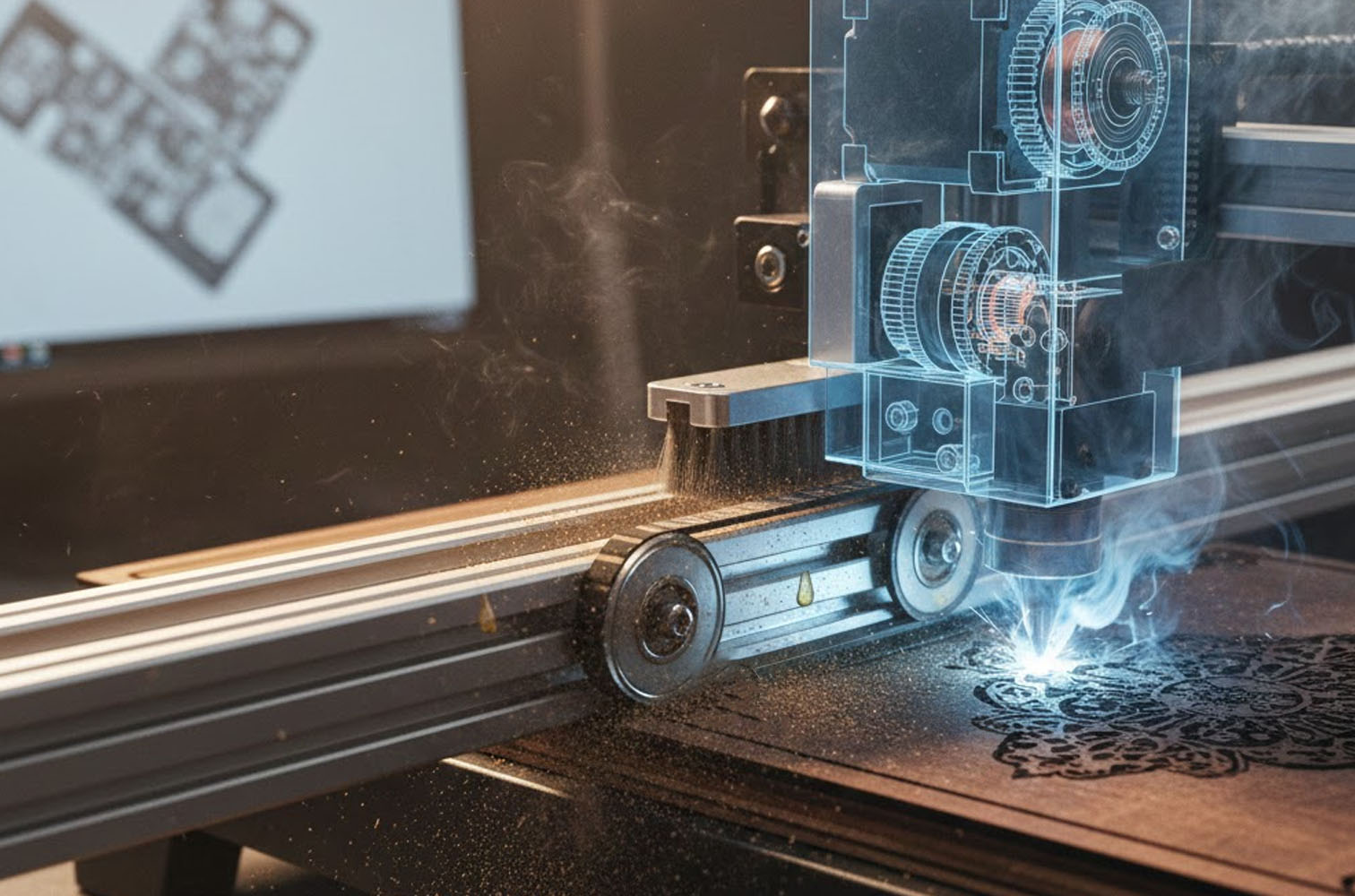

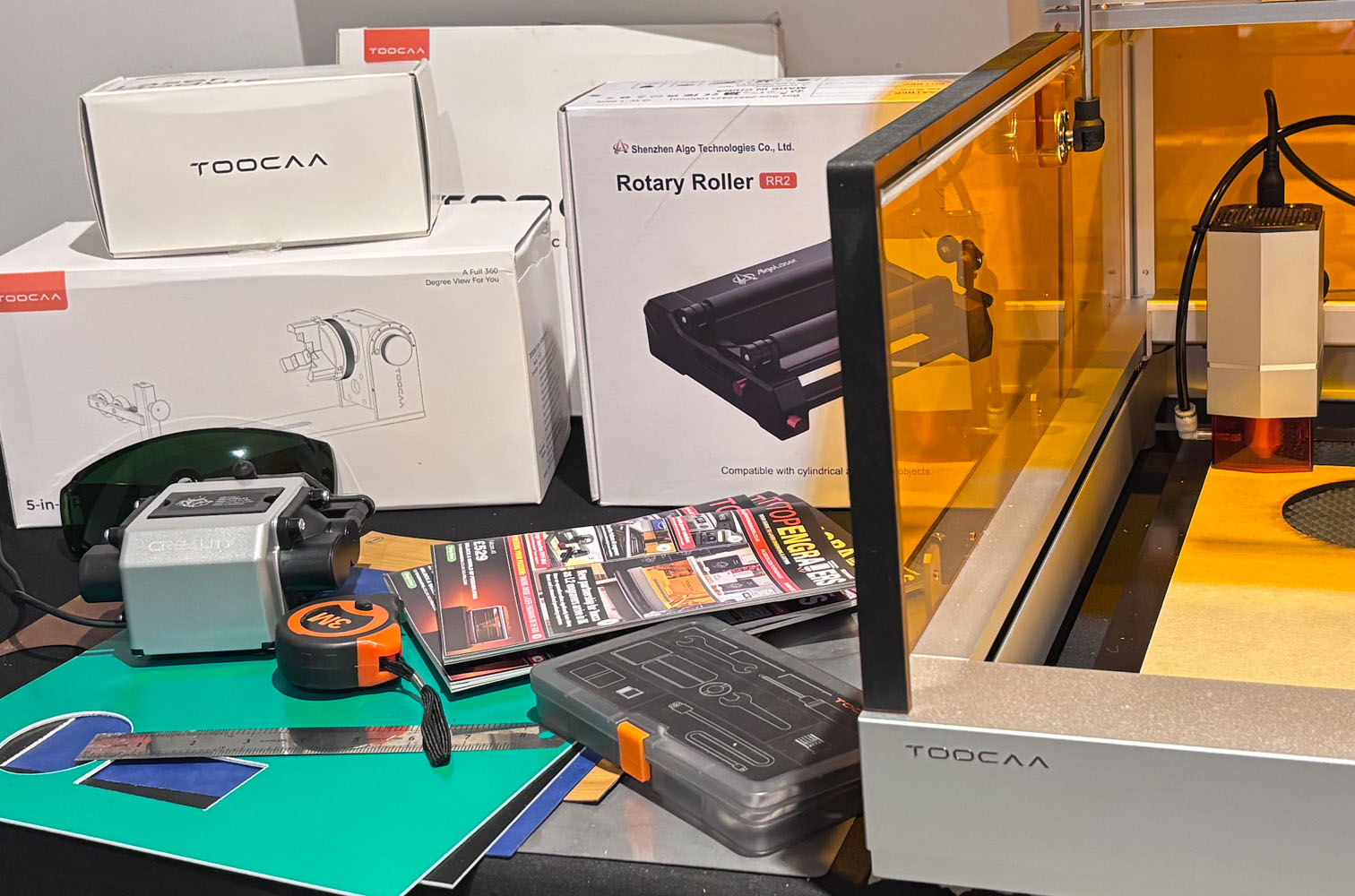

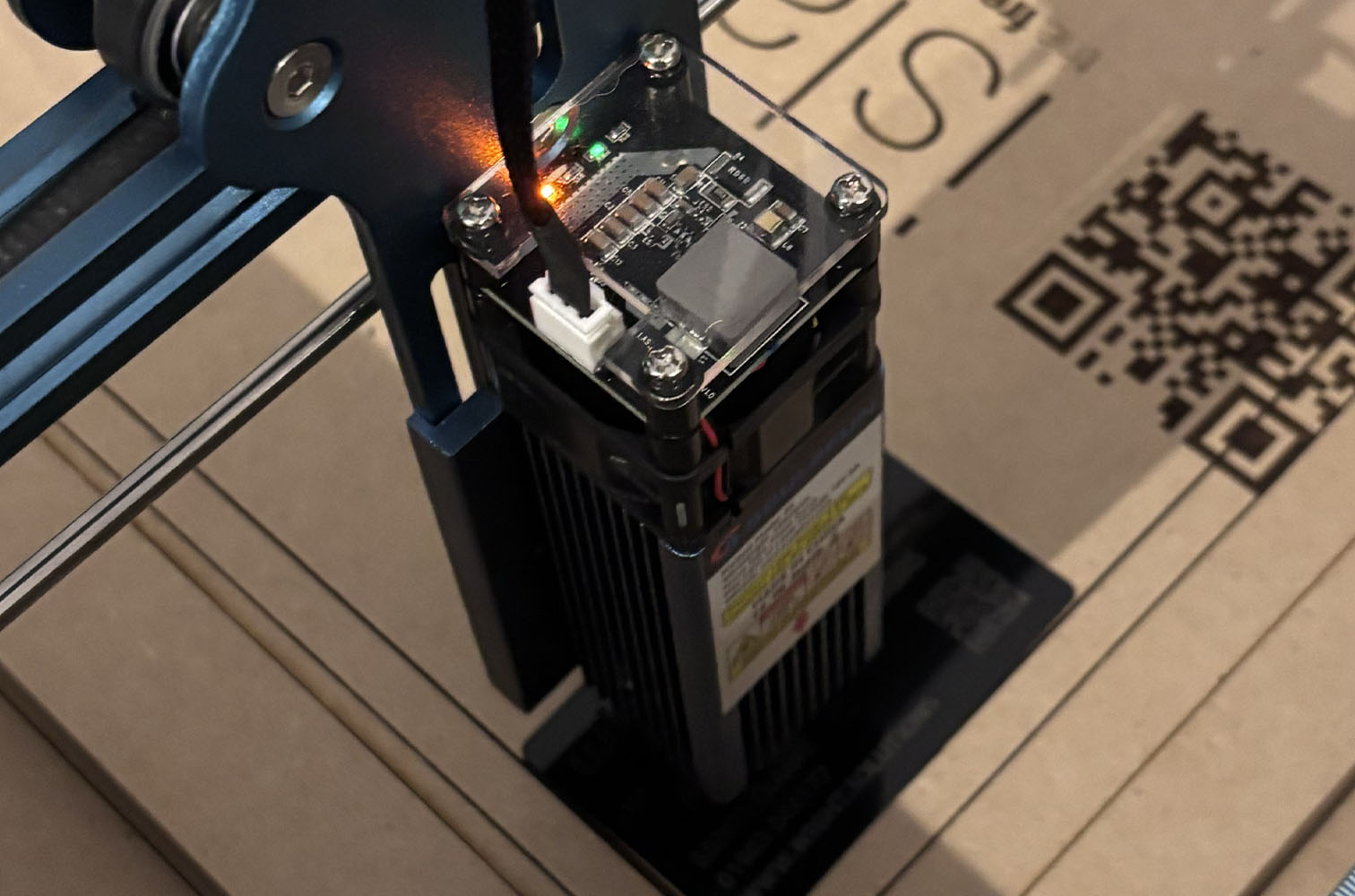

Diode lasers have revolutionised crafting and small-scale manufacturing, offering incredible precision and versatility. However, not all materials are created equal, and some pose significant risks when exposed to diode laser beams.

Understanding which materials to avoid is crucial for safety, preventing damage to your equipment, and ensuring successful project outcomes.

Why Some Materials Are Off-Limits:

Diode lasers, unlike CO2 lasers, operate at specific wavelengths that interact differently with various materials. This interaction can lead to unintended chemical reactions, fire hazards, or the release of toxic fumes. Here are some of the most common materials and products you should avoid engraving or cutting with a diode laser:

- PVC (Polyvinyl Chloride) and Vinyl: PVC and vinyl release chlorine gas when heated, which is highly corrosive and toxic. This gas can damage your laser engraver and pose severe health risks. Exposure to chlorine gas can cause respiratory problems, eye irritation, and long-term health issues.

- ABS (Acrylonitrile Butadiene Styrene): ABS plastic releases styrene gas when burned, a known carcinogen. Styrene gas is harmful to the respiratory system and can cause dizziness, headaches, and nausea.

- Polycarbonate (PC): While polycarbonate can be engraved under specific, carefully controlled conditions, it’s generally best avoided. It releases toxic fumes and can produce a messy, undesirable finish. The fumes can be harmful to respiratory systems, and the finished product can be of poor quality.

- HDPE (High-Density Polyethylene): HDPE can melt and produce unpleasant fumes. Although not as toxic as PVC, it can still cause irritations. The melted plastic can create a mess, and the fumes can cause respiratory discomfort.

- Materials Containing Halogens (Fluorine, Chlorine, Bromine, Iodine): Halogens release corrosive and toxic gases when heated. These gases can damage your laser engraver and pose serious health risks.

- Certain Foams: Many foams, especially those containing polyurethane, release toxic fumes when burned. These fumes can be harmful to the respiratory system and can cause irritation.

- Treated Wood: Wood treated with chemicals, such as pressure-treated lumber, can release toxic fumes when burned. The fumes can be harmful to the respiratory system, and the chemicals can contaminate your workspace.

- Mirrors and Reflective Materials: Diode lasers can reflect off mirrors and other reflective surfaces, potentially causing damage to the laser or surrounding objects. This can lead to fire hazards and damage to your equipment.

- Explosive Materials: This should go without saying, but any material that is explosive should never be placed in a laser engraver. Obvious safety hazard.

- Food with High Water Content: While some food engraving is possible, high water content foods can steam and cause uneven engraving, and can cause unsanitary conditions within the machine. Poor quality results and potential damage to the machine.

Prioritise Safety:

Always prioritise safety when operating a diode laser. If you are unsure about a material, it is best to avoid it. Always ensure proper ventilation when laser engraving, and wear appropriate safety gear. By staying informed and cautious, you can enjoy the benefits of diode laser engraving while minimising risks.

Editor at TopEngravers. Specialising in reviews of new laser engraving products, practical engraving tips, and detailed engraver guides.