ACMER launches a groundbreaking 3-in-1 laser and CNC machine

In a monumental leap for hobbyists, creators, and small businesses, ACMER has officially launched its new flagship machine, the ACMER X1, on Kickstarter. Heralded as the world’s first system to seamlessly integrate a 120W water-cooled diode laser, a 4W IR laser, and a powerful 200W CNC router into a single smart, studio-ready platform, the X1 is poised to penetrate industrial-grade manufacturing.

This all-in-one device promises to deliver unparalleled power, precision, and versatility at an accessible price point, fundamentally reimagining the future of personal manufacturing.

The ACMER X1 is not merely an incremental upgrade; it is a paradigm shift. For years, creators have had to choose between multiple expensive, bulky machines to achieve the results they needed. The X1 eliminates this compromise by offering a three-in-one solution that covers a vast range of material processing needs, from intricate engraving to heavy-duty cutting and milling. The machine’s innovative design and proprietary technology are a testament to ACMER’s commitment to putting industrial capabilities within reach of every creative mind.

At the heart of the ACMER X1’s revolutionary design is its triple-threat functionality. The 120W diode laser is a powerhouse for cutting and engraving a wide array of materials, including wood, acrylic, and leather, with remarkable speed and efficiency. Its ability to slice through 40mm solid wood in a single pass is a game-changer, setting a new benchmark for diode laser performance. The system is also 1.8x faster than traditional models, boasting cutting speeds of up to 30,000 mm/min.

Complementing this is a precision-engineered 4W IR laser, which excels at engraving metals, ceramics, and other challenging materials with exceptional detail and contrast. The IR laser module is designed for higher energy efficiency and deeper, sharper lines, opening up new creative possibilities for users who work with a diverse material palette. Finally, the integrated 200W CNC router module provides a robust solution for relief carving, milling, and cutting, transforming the machine into a comprehensive fabrication workshop.

One of the most significant technological innovations in the ACMER X1 is its IntelliCool™ Precision Thermal Control System. Unlike outdated air-cooled solutions that can suffer from performance degradation and limited lifespan, the X1’s smart thermal system utilizes precision water channels and high-efficiency heat sinks. This ensures zero fluctuation in performance, providing round-the-clock reliability and a tenfold longer lifespan for the laser components. This advanced cooling system is a core reason why the X1 can sustain high-power operation, enabling creators to tackle demanding projects without fear of overheating or inconsistent results.

The X1’s versatility is further enhanced by its swappable heads and a dual work zone design, catering to both large-scale projects and fine-detail work. The machine boasts the world’s largest dual work area, featuring a massive 4’1″ x 8’4″ full-sheet zone compatible with standard 4′ x 8′ US/EU panels, and a dedicated 1’3″ x 1’3″ detail zone. The full-sheet processing capability, supported by a one-piece Y-axis frame, allows creators to handle big jobs with unwavering accuracy, while the built-in HD camera in the detail zone ensures pinpoint precision for intricate patterns and detailed logos. This dual functionality is a major selling point, allowing a single machine to transition from high-volume production to delicate, bespoke creations seamlessly.

The ACMER X1 is also built with an uncompromising focus on safety. Its fully enclosed design, combined with an “All-Round Safety System,” provides a secure environment for operation. This system includes features such as auto fire detection, an emergency shutoff button, and a smart smoke exhaust system, ensuring a clean and worry-free experience for the user. These safety measures are critical for both hobbyist settings and professional workshops, providing peace of mind while handling powerful tools.

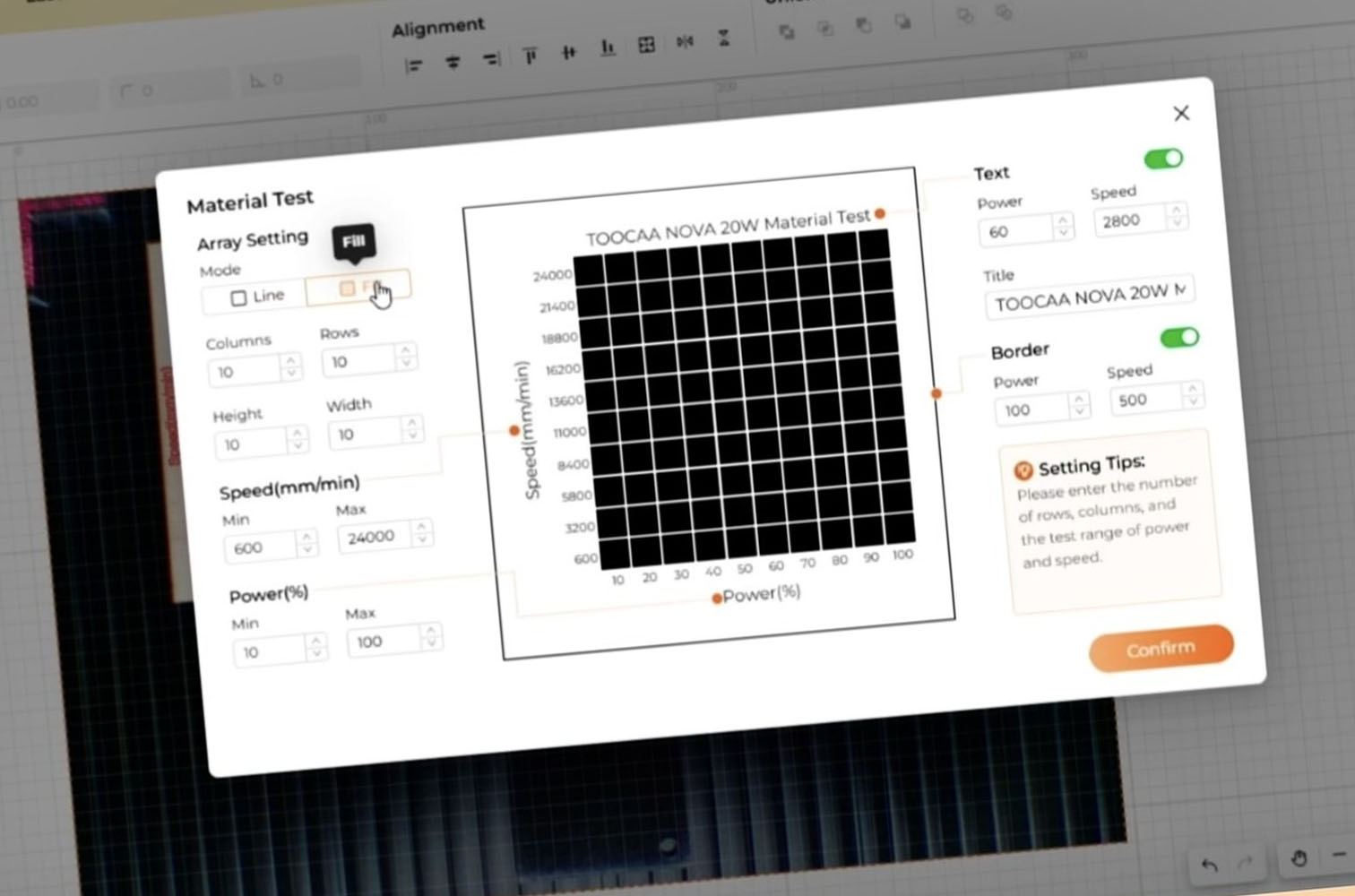

Beyond its impressive hardware, the ACMER X1 comes with free proprietary control software, saving users from the annual costs and steep learning curves associated with third-party software licenses. This user-friendly software is designed to cut operator training time in half, empowering both experts and beginners to harness the full potential of the machine right out of the box. The software integrates seamlessly with the hardware, offering smart precision tools like auto-focus, curved surface engraving capabilities, deep multi-layer cutting, and camera positioning to reduce setup time by up to 70% and minimize errors and material waste.

ACMER, founded in 2021 by a team of two MIT PhDs, was born from the belief that industrial-grade tools should not be exclusive to factories but accessible to every creator. The company’s mission is to merge power, precision, and accessibility as digital manufacturing shifts from industrial to personal. The ACMER X1 represents the culmination of years of research and development in high-performance diode and IR systems, compact industrial rails, and smarter software. It is a bold statement on what personal manufacturing can become—a new format, a new standard, and a powerful engine for creativity.

By launching on Kickstarter, ACMER aims to build a community of early adopters who can help bring this revolutionary machine to life. The campaign offers backers the opportunity to be among the first to own this state-of-the-art system, providing them with the tools to transform their workshops into powerhouses of creativity. With its triple functionality, advanced cooling, dual work zones, and comprehensive safety features, the ACMER X1 offers an unprecedented value proposition, reducing total equipment investment by up to 80% compared to purchasing separate machines. This makes industrial-grade capabilities a reality for a new generation of makers.

The ACMER X1 is more than just a machine; it’s a new standard for a new era of personal manufacturing. It’s an invitation for creators to imagine bigger and build more, with a single, smart platform that masters everything from intricate micro-detailing to true full-sheet processing.

The campaign page offers a deep dive into the full specifications and features, inviting the community to support a project that is set to redefine the creative landscape.

Editor at TopEngravers. Specialising in reviews of new laser engraving products, practical engraving tips, and detailed engraver guides.